We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Engineered Oak Flooring | Buying Guide

Ready To Commit To Your Perfect Engineered Oak Flooring? Here Are Some Buying Tips To Guide You Through...

Thinking of buying an engineered oak wood floor but not sure where to start? Our step-by-step buying guide will help you find the perfect floor for you and your home.

Step One | Get To Know The Product

Before buying your floor you need to do your research to ensure that it is the right floor for you. It's good to understand engineered wood and how it differs from solid wood before you decide to buy it. If you don’t, then you might end up with a floor that's unsuitable or over budget.

What is Engineered Oak Flooring?

Engineered flooring is made up of a solid hardwood top layer and a base of 3-12 layers of plywood which, when laid, replicates solid wood flooring, creating a finish that's identical to the naked eye, at a fraction of the cost.

One of the defining characteristics of engineered oak flooring is that it is made up of different layers, these structural 'sublayers' run in different directions, which makes it incredibly stable. Engineered wood flooring is available in a wide range of finishes and colours, as well as different styles such as parquet and herringbone flooring.

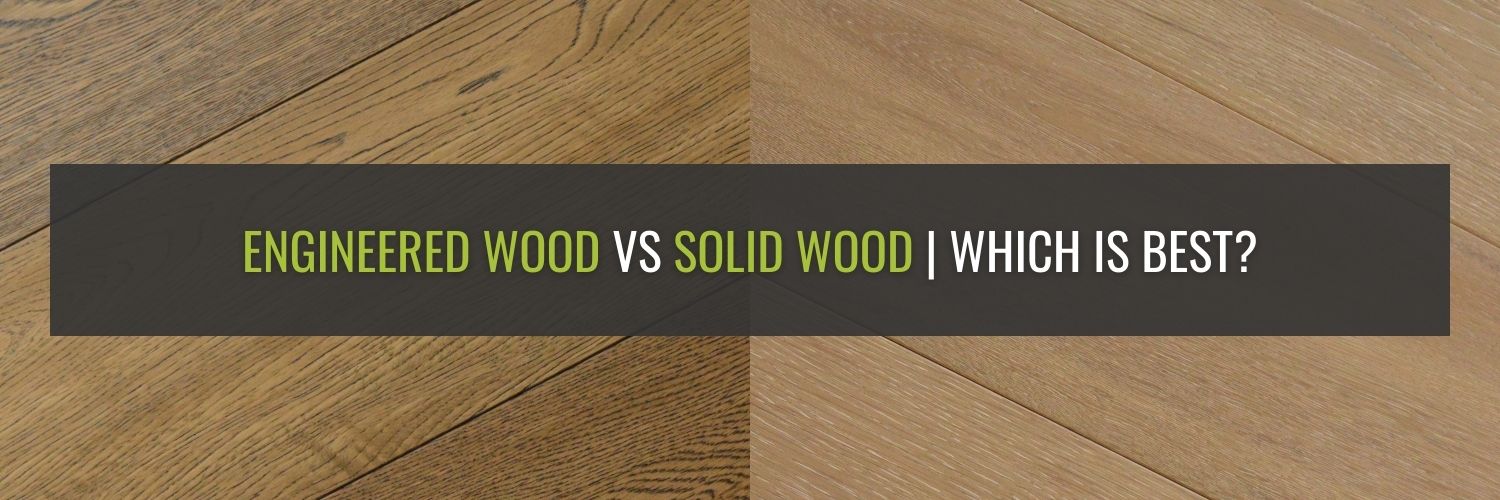

What’s the difference between Solid Wood & Engineered Wood Flooring?

Engineered wood is designed to mimic the look of solid wood flooring perfectly. There's no difference when laid to the naked eye, however, the two types of flooring act and react very differently to one another.

Engineered wood flooring is, generally, more stable than solid wood flooring, so it can cope with higher temperatures and moisture. Whereas solid wood flooring could expand and warp if there’s a significant, rapid change to temperature and/or humidity. Generally, this is why engineered wood flooring would be a better fit for rooms where changes in temperature and humidity happen frequently such as kitchens.

Both floors must be acclimatised to your home before installation. However, the time varies for each floor. Engineered wood should be acclimatised for up to 48 hours whereas solid wood should be acclimatised for up to 7 days. This helps your flooring adapt before fitting, minimising potential issues later on.

Is An Engineered Oak Floor Worth It?

As with all engineered wood flooring, oak engineered flooring offers the exact aesthetic and feel of solid wood at a much more budget-friendly price. Possibly our most popular flooring style, oak is available in a wide variety of colours, styles, and finishes, with a price range to suit any budget.

If you're looking for a beautiful oak floor that won't break the bank, we'd definitely recommend engineered flooring!

Benefits of Engineered Oak Wood Flooring

Durability

Engineered oak wood flooring is extremely popular due to its long lifespan. The wood is made up of multiple layers of plywood that are bonded together and then topped off with a solid wood top layer. Since it is made this way, the flooring is incredibly tough and long-lasting.

The top layer, or 'wear layer' can be sanded and refinished, meaning it will look its best for many years.

Lifespan

Thanks to the durability and stability of engineered wood floors they can last for decades. If looked after properly, engineered wood floors can last up to 30 years.

Stylish

Engineered oak wood floors are extremely stylish giving you the look of a solid wood floor due to its solid wood top layer. They’re a timeless and beautiful floor that will add a sense of style and sophistication to your home. Engineered oak wood floors also come in a wide selection of colours, finishes, and styles for you to choose from so there’s something for everyone, no matter your style.

Oak is one of the most popular wood types on the market, which will never go out of style, perfect if you're looking for a long-term option.

Won’t Break The Bank

One of the many great advantages of engineered oak wood flooring is that it won't cost you an arm and a leg. Engineered oak wood flooring is cheaper than traditional solid wood flooring but the best thing is it still looks expensive! So, if you want an expensive looking floor for half the price then engineered oak wood flooring is the floor for you!

Easy to install

Engineered flooring is famously simple to lay which again adds to its ever-growing popularity. Lending itself perfectly to both professional and DIY installation. Greater temperature resistance In comparison to traditional wood flooring, engineered wood flooring is more resistant to moisture and changes in temperature. This means that you can install engineered wood flooring in places where traditional wood flooring wouldn’t be suitable such as your kitchen.

Our most popular fitting type; tongue and groove, can be laid by any competent DIY'er, without the need for gluing to a subfloor.

Our Top Pick Engineered Oak Floors

Still unsure? Take a look at our top pick engineered oak wood floors!

Step Two | Budget

Before getting your heart set on one of our engineered oak floors it’s important to consider what type of budget you have. Although engineered wood floors are cheaper than solid wood floors, the prices do vary depending on the wood grade and finish.

Engineered oak is generally cheaper than other engineered wood species such as walnut, with other common factors that affect the price of engineered oak wood floors including; the colour of the floor (as the rarer the colour the more expensive it will be), the thickness of the boards and how thick the wear layer is (the top layer of solid wood).

Regardless of how much or how little your budget is, we are confident that you will find the perfect engineered oak wood floor that will suit you but more importantly, suit your budget.

Step Three | Fitting

Another factor to consider is who will be fitting your new floor. Fitting your floor, yourself will save you money but can be a hassle, especially if you’re new to floor installation. That said, as engineered flooring is generally laid using a 'floating floor' method, meaning it simply sits on top of an existing sub-floor, it's well within the capabilities of most novices and DIY enthusiasts alike.

Whilst hiring a professional fitter can be more expensive, it can reduce stress, especially if your flooring is part of a wider renovation or house move. A professional fitter will also have the right knowledge and experience to fit your flooring if it's in a particularly awkward room or on stairs.

Step Four | Suitability

An important factor to consider is the suitability of the floor. For example, if you’re looking for a floor for your bathroom then an engineered oak wood floor wouldn’t be suitable. It’s important to consider the suitability of the floor, for the room you want to fit it in to make sure you’re making the right choice and to prevent your floor from becoming damaged.

Generally, engineered oak flooring can be used in all rooms of the house, except the bathroom which has a higher moisture level. Thicker wear layers are recommended for rooms where heavier footfall is expected too, such as hallways and stairs.

Engineered Oak Flooring Room by Room

Living Room

Transform your entire living space with a new engineered oak floor from Flooring365! Engineered oak floors are incredibly stylish giving you the look of a solid wood floor at a fraction of the price. So, if you’re looking for a timeless and beautiful floor to breathe life back into your living space then our engineered oak floors will be exactly what you’re looking for.

Dining Room

Engineered oak wood flooring is a low-maintenance floor and is ideal for busy families. You won’t have to worry about spills, stains, or grubby paws damaging your floor as a quick sweep and mop will have your flooring looking as good as new.

Bedroom

An engineered oak wood floor would make a perfect addition to your bedroom. It’s a timeless and beautiful looking wood floor. If you’re wanting warmth and comfort, why not add an underlay? It will add an extra layer to your flooring making it softer and more comfortable beneath your feet.

Hall and Landing

Whatever flooring you have in this part of your home it needs to be both inviting and able to withstand traffic in these high-use areas. Our range of engineered oak flooring is incredibly hard-wearing and durable so will be able to withstand high volumes of traffic.

Bathroom

Engineered oak flooring isn’t waterproof so we don’t recommend it for use in bathrooms. If you’re looking for a floor suitable for bathrooms, we recommend an Oak LVT or some waterproof laminate options, which offer a wood effect, whilst still being able to withstand higher levels of moisture and humidity.

Kitchen

Due to its unique composition, engineered wood floors are durable enough to withstand high volumes of activity, as well as moderate levels of moisture and humidity.

Although they’re not 100% waterproof, engineered wood flooring can work well in kitchens. We recommend using a lacquered floor in kitchens, which provides an impermeable top layer and offers greater protection.

As long as you clean up small spillages as soon as possible, your engineered wood floor will look great in your kitchen for years to come.

Step Five | Maintenance

Engineered oak wood flooring is highly durable and will withstand the pressures of any busy household. That said, there are a few things you can do to keep your flooring in excellent condition and looking as good as when it was first laid.

- A daily sweep or clean with a damp mop.

- Mopping up spillages as soon as possible to avoid staining.

- Reapply oils on a regular basis, ensuring your floor has maximum protection.

Despite engineered oak being extremely durable, damage to your floor can still occur however, engineered wood floors can be sanded and refinished meaning, if there’s any damage to your floor, you’re able to erase it with relative ease.

Step Six | Style and Finishes

You’ve learned all there is to know about an engineered oak wood floor, you know which rooms to fit it in and you also know how much you’re wanting to spend on your floor. So, now it's time for the fun part! Choosing the style and finish you would like.

Style

Our engineered oak flooring range comes in a number of different colours, styles, and finishes. It all comes down to your personal preference. Here at Flooring365, we have a wide range of engineered oak wood floors for you to choose from. The two main styles that our engineered oak wood floors come in are normal planks and parquet.

Finishes

Brushed & Lacquered

Brushed and lacquered flooring has been lightly brushed using a steel wire wool during production which removes the upper layer of wood grain. This exposes the natural qualities and charm of the wood without causing any damage.

The wood is then protected with a lacquer. The lacquered finish can be found in either a matt finish or a satin matt finish. The lacquer adds additional strength and protection to the wood whilst maintaining its natural character and charm.

Brushed & Oiled

Brushed and oiled flooring is prepared in a similar way to brushed and lacquered, however, the wood is protected with an oil and is ready to be used once installed.

Distressed

Distressed engineered flooring is made in a similar method to aged flooring, adding texture to the surface, including bumps and scrapes, during production to give a worn feel but usually involves using more rustic boards, meaning a greater depth of grain, knots, and pattern. Distressed flooring is ideal if you’re looking for the stability of a new, engineered board, with the appearance of an antique, reclaimed floorboard.

Handscraped

With a handscraped engineered wood floor, the surface of the hardwood has been scraped, by hand, to add extra definition and uniqueness.

Lacquered

Lacquered is a clear (invisible) or coloured varnish that dries to produce a hard, durable finish. It’s applied to the flooring to reduce the damage caused by spillages, effectively creating a thin surface layer that prevents liquids from seeping into wood grains.

A wooden floor with a lacquered finish can be found with either a matt finish or a satin matt finish. The lacquer adds additional strength and protection to the wood, making it ideal for heavier traffic areas, whilst maintaining its natural character and charm.

Oiled

An oiled finish has many benefits and is extremely versatile. Oil provides deeper protection than lacquer as the oil seeps into the wood grain which protects the boards. However, as there is no surface layer created, oiled flooring usually requires greater maintenance and care over spillages. An oiled finish often comes in many different styles of finishes, with matt or satin oils available, as well as coloured oils which totally change the look of the floor.

Aged

Aged flooring is created by adding light wear to the surface of engineered wood planks, such as bumps and scrapes, to create an established, worn look that creates the illusion of flooring that has been laid for years. Varying levels of ageing are available, depending upon your style preference, giving an impression of short and longer-term wear.

Unfinished

An unfinished engineered oak floor is simply raw material. It hasn’t gone through the finishing process of having a stain or protective layer of oil or lacquer put onto it. However, an unfinished engineered oak floor will require treatment or a protective layer after fitting and before use. The main benefit of an unfinished engineered oak floor is that it comes in a wider range of styles thanks to the availability of oils, waxes, or stains.

Step Seven | What’s Going Underneath

Another important thing to consider is, what is going underneath your engineered oak floor.

Underfloor Heating

In comparison to solid wood flooring, engineered oak is more resistant to moisture and changes in temperature so, our engineered oak flooring range is suitable to fit over underfloor heating. However, our floors are only suitable for water-based underfloor heating as electric heating can cause heat spikes; areas of rapidly changing temperatures that can cause damage to the boards.

So, yes, you can fit your engineered oak floor over underfloor heating as long as it is water-based. If you’re planning on fitting your engineered oak wood floor with underfloor heating, then there are a few things to consider; the thickness of your flooring and the underlay you use.

We recommend using boards around 14-16mm thick, as a thinner board will help dissipate heat more effectively.

Underlay

Engineered wood flooring is dense enough to be laid without an underlay. However, for a professional finish and the best possible results, we always recommend using an underlay.

Underlay is a thin layer of cushioning material that is placed between the subfloor and the wood flooring. There are a couple of advantages to installing underlay under your engineered wood floor for example, it will give you an even subfloor. Installing underlay will smooth out your sub-floor and make it even, so you’ll be able to lay your engineered oak floor on an even ground which will offer your floor more stability. Underlay can also help with comfort. It will add an extra layer to your flooring making it softer and more comfortable beneath your feet. It will also help with insulation, making your rooms warmer and improving energy efficiency.

Step Eight | Delivery

You’ve bought your dream floor so now it’s time to sit back, relax and wait for your floor to be delivered … Almost!

There are a few important factors you’ll need to consider so when your floor does get delivered, you’re ready and prepared to receive it. Flooring can be bulky, heavy, and awkward to deliver, so it’s worth keeping in mind that you’ll probably need to set some time aside for your delivery. Whilst most delivery companies will accommodate your requests as much as possible, they’ll usually specify a ‘kerbside drop’ which means they’ll unload your flooring on a pallet at the roadside.

With this in mind, be sure to have at least one person at your home on delivery day that’s willing to get stuck in, moving your new flooring indoors. Before your delivery day, think about where you’re going to store your flooring, in the short term, before your installation. Ideally, somewhere clean, dry, and easy to access. It goes without saying that, to make things easier on delivery day, make sure you clear your path of any obstruction or hazards, remember, you may struggle to see your step when you’re carrying the flooring! Alternatively, you could collect your flooring directly. Engineered wood flooring usually comes in packs under 2 meters, which means they’ll be pretty easy to pack in your car or van but keep in mind they will be heavy in larger quantities.

Acclimatize your flooring We recommend acclimatising your engineered wood floor so that it can become used to the conditions of your home before it is installed. Even though it is more stable than solid wood flooring, engineered oak floors will still move slightly so it’s best to let them acclimate before installation. We recommend a minimum of two days between receiving your floor and installing it. Remove Furniture Although it can be a pain, we recommend removing all furniture from the room where you want to install your engineered wood floor. Not only will it save you time by not having to constantly re-arrange your furniture, but it could also minimize the risk of damaging your new floor.

Step Nine | Installation

Our engineered oak wood floors are relatively easy to install. You can choose between the tongue & groove method or the Click Lok system.

Tongue & Groove

A traditional method of fitting flooring, tongue & groove simplifies the installation process. Its main purpose is to easily fit groove boards and joints together with minimal stress or effort involved. Tongue & groove flooring usually has a simple profiled edge, where two pieces of flooring simply ‘push together’ and PVA glue is used to hold everything in place. Whilst it can be slower to fit than other methods, some customers prefer the peace of mind a glued, tongue & groove flooring provides.

Click Lok System

Click Lok flooring has a profiled edge which creates a glue-free, interlocking fitting system, meaning it can be laid more easily, and relatively hassle-free. The Click Lok system, used predominantly in engineered and laminate flooring installation is intended to make laying flooring easier for any DIY enthusiast, by simply pushing, dropping, or clicking boards into place. If you’re considering, Click Lok it’s important to think about the underlying surface on which your new engineered oak flooring will be laid. Uneven surfaces make Click Lok much more difficult to fit and keep in place, which often means the need for levelling underlay.

Floating Floor (Sub Floor)

Engineered wood floors are usually laid using the ‘floating floor’ method, essentially sitting on top of an existing subfloor, without any adhesion. Although installing over a subfloor is much easier (than on a fixed floor, where gluing to a base is needed), you will need to prep before fitting. Ensure your subfloor is level, clean, and dry, free from any lumps or bumps. If you need to, be sure to use an underlay that will overcome any major discrepancies. Remember, the better your subfloor, the easier your floor will be to fit.

Conclusion

With our engineered oak wood flooring, step by step buying guide we are confident that you will find the perfect engineered oak floor for you and your home! Still have questions? Don’t worry! You can always give us a quick call where one of our sales team will be able to help you with any questions/queries you may have! Or you can request a call back on the website.

engineered-oak-flooring-buying-guide